How is galvanized sheet produced?

Nov.15.2024

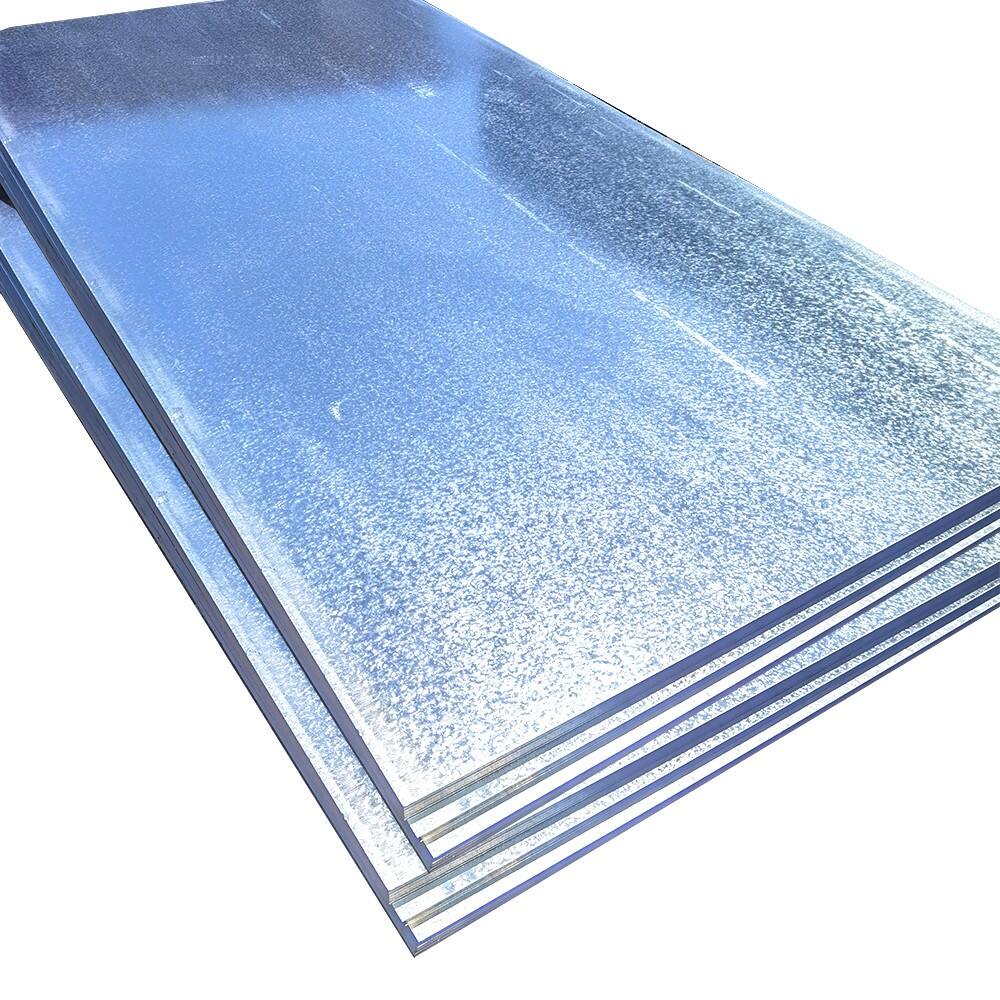

Galvanized steel is widely recognized for its durability and corrosion resistance. This article takes an in-depth look at galvanized steel production process, classification, installation and other expertise to provide valuable insights for manufacturers and consumers.

The production process of galvanized sheet mainly includes the following steps:

Raw material preparation:

Select high quality cold/hot rolled steel coils as the base material.

Cleaning:

Remove oil, oxides and other impurities from the surface of the steel coil using chemical cleaners or acid washing to ensure the adhesion of the galvanized layer.

Galvanizing:

The cleaned steel coils are passed through a molten zinc bath for hot dip galvanizing. The coils are dipped in the zinc solution, which causes the zinc to react with the steel surface to form an alloy layer and a galvanized layer.

Cooling:

The galvanized steel coils are passed through a cooling unit to reduce their temperature and solidify the galvanized layer.

Shaping and cutting:

The cooled galvanized sheet is shaped, trimmed and cut to the required specifications and dimensions.

Surface Treatment:

Depending on the requirements, the galvanized sheet is subjected to further surface treatments such as painting, coating or rustproofing to improve its corrosion resistance and aesthetics.

Classification of Galvanized Steel Sheets

Galvanized steel sheets can be classified based on their coating method and thickness:

1. Hot-Dip Galvanized Sheets: Coated by dipping into molten zinc, providing a thicker layer of protection.

2. Electro-Galvanized Sheets: Coated through an electroplating process, offering a thinner layer with a smoother finish.

3. Thickness Categories: Available in various thicknesses to suit different applications, typically ranging from 0.3 mm to 3.0 mm.Thickness can also be customized

Transportation and Installation Tips

When transporting and installing galvanized steel sheets, consider the following tips:

· Handling: Use gloves to prevent skin contact with sharp edges and to avoid contaminating the surface.

· Transportation: Securely stack sheets to prevent bending or damage during transit.

· Installation: Ensure proper support and alignment during installation to maintain structural integrity. Use appropriate fasteners that do not react with zinc to prevent corrosion.

EN

EN