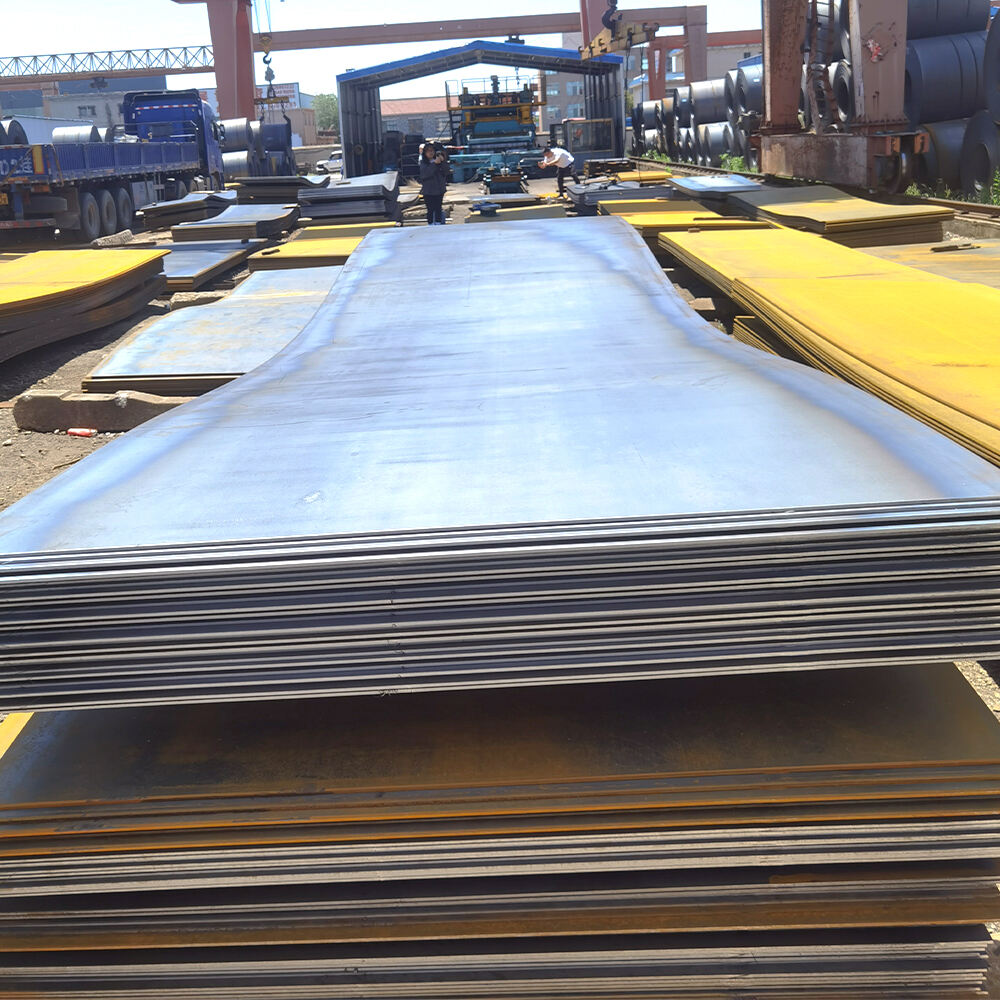

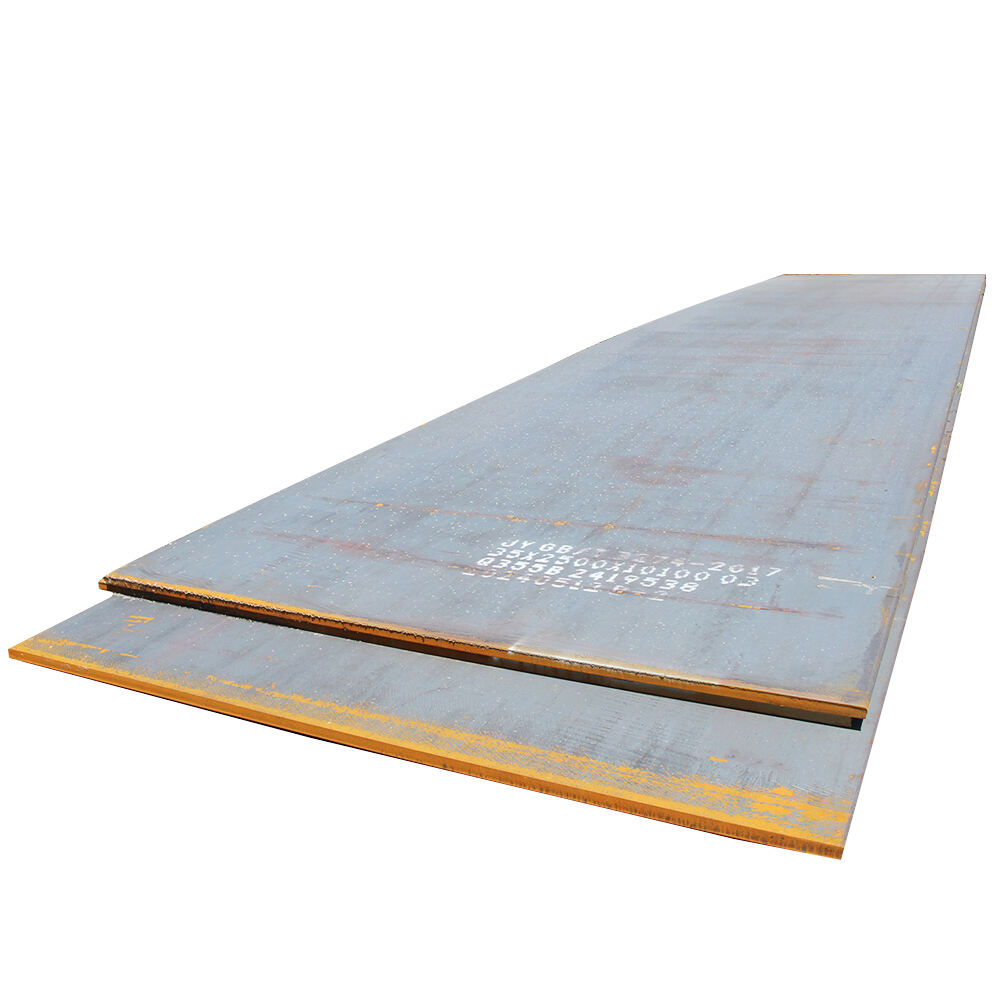

low carbon steel sheet

The low carbon steel sheet is a versatile material characterized by its excellent strength and formability. Mainly used in manufacturing and construction, it serves a variety of functions ranging from structural support to aesthetic finishes. Technologically advanced, it is produced through a refined process ensuring high durability and consistent quality. With a carbon content of approximately 0.05% to 0.25%, it is softer than higher carbon steels, allowing for easy cutting, shaping, and welding. Its applications are widespread, from automotive parts and appliances to industrial equipment and construction materials, making it a staple in various industries.